Hey Everyone, welcome back to Technique Tuesday.

Last week I started talking about the variety of stabilizers available to quilters as well as the how and why about the different types. Today is all about the leave-in stabilizers – these tend to be the stabilizer I use the most..

Leave-in Stabilizer

Usually the leave-in stabilizer has a fusible side and is ironed to the fabric rather than having to be pinned. Once adhered to the fabric it stays in the quilt. There are woven and non woven fusible stabilizers.

Woven

I use a woven fusible stabilizer from Pellon called Pellon 987F Fusible Fleece when I am making a quilt – especially a baby quilt such as Animal Party or Ocean Party. The fusible fleece is low loft, soft and compresses enough after quilting that you don’t even know it is there. It works great with the cotton quilting fabrics in all kinds of projects such as bags, quilts and crafts.

Originally I started using a fusible fleece product called Vilene H630 when I was living in Australia. I do like it better than the Pellon product as it is softer, less dense and compresses better in the project. It seems to have a less synthetic feel, the Pellon product has a rough feel to it. Anyway, it is hard to get the Vilene product here in Canada so I use the Pellon.

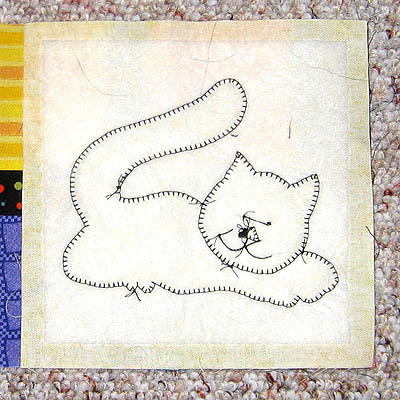

When I use the fusible fleece to back an applique shape in a block such as the one below, I cut the stabilizer an inch smaller all the way around. This way it won’t get caught in the seams as I sew the pieces together. If I put it right to the edge of the fabric then it would be sewn into the seam and create bulk along the seam line resulting in an uneven seam. I like my seams to lie nice and flat.

When using stabilizers make sure to follow the manufacturer’s instructions for how to use. I have found that with the Pellon fusible fleece that a hot iron with lots of steam works best to activate the glue to adhere to the fabric. I usually iron directly onto the fleece rather than from the top of the quilt as the instructions say – only because I usually have appliqué designs on the front and do not want to iron directly on them. A Teflon sheet or parchment paper is not needed for this application.

Non-Woven

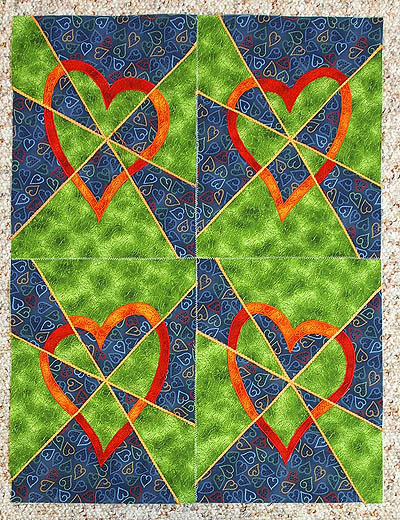

The non-woven fusible stabilizers I use more in art quilts that need a bit more stiffness because of couching and embellishing especially if I am doing these techniques prior to being sandwiched for quilting. This Stitch Along Sunday piece was built on the non-woven stabilizer Vilene H250 by fusing the pieces to it and then couching over the raw edges of the fabrics to look like seams.

The back of the piece.

The front of the piece.

A hot iron to the back side of the Vilene works well to adhere the glue to the fabric and then for good measure I run the hot iron over the fabric to make sure all is stuck together depending on what is on the front of the piece. I don’t use parchment paper or an appliqué sheet as I find that that extra layer is a hinderance to activating the glue.

Sometimes they are used even in conjunction with the batting layers. The pieces made in Carol Taylor’s class I used the fusible non-woven stabilizer as part of the sandwich of layers to give a bit more stability to the piece. You can’t see it in the piece but it definitely added a stiffness to the piece for couching.

Another example of when I used this type of stabilizer is in a class I took with Dena Crain, a quilt artist/instructor from Kenya. The stabilizer is Vilene H250 made by a German company. In her class Structured Fabrics the fabrics were fused and sewn to the stabilizer. The image below shows the back of the piece – the white areas are the stabilizer – only parts of the stabilizer are seen because the pieces were woven together.

Non-Fusible

There are also stabilizers that are not fusible but yet are left in the project when finished. I have used a few of these products through the years. I find that the non-woven ones are easier to use as they can be treated as a base for the work and the fabrics sewn to them creating the quilt top. The woven ones I find need to be anchored to the work with either pins or a spray basting glue.

In short I tend to stick with either the Pellon 987F or the Vilene H250 for my leave-in stabilizers – I am not sure what I am going to do when I run out of the Vilene that I have but I’ll cross that bridge when I come to it. I am sure Pellon must have a suitable substitute.

See you next week when I talk about wash-away or soluble stabilizers.

Happy Quilting!

Trackbacks/Pingbacks